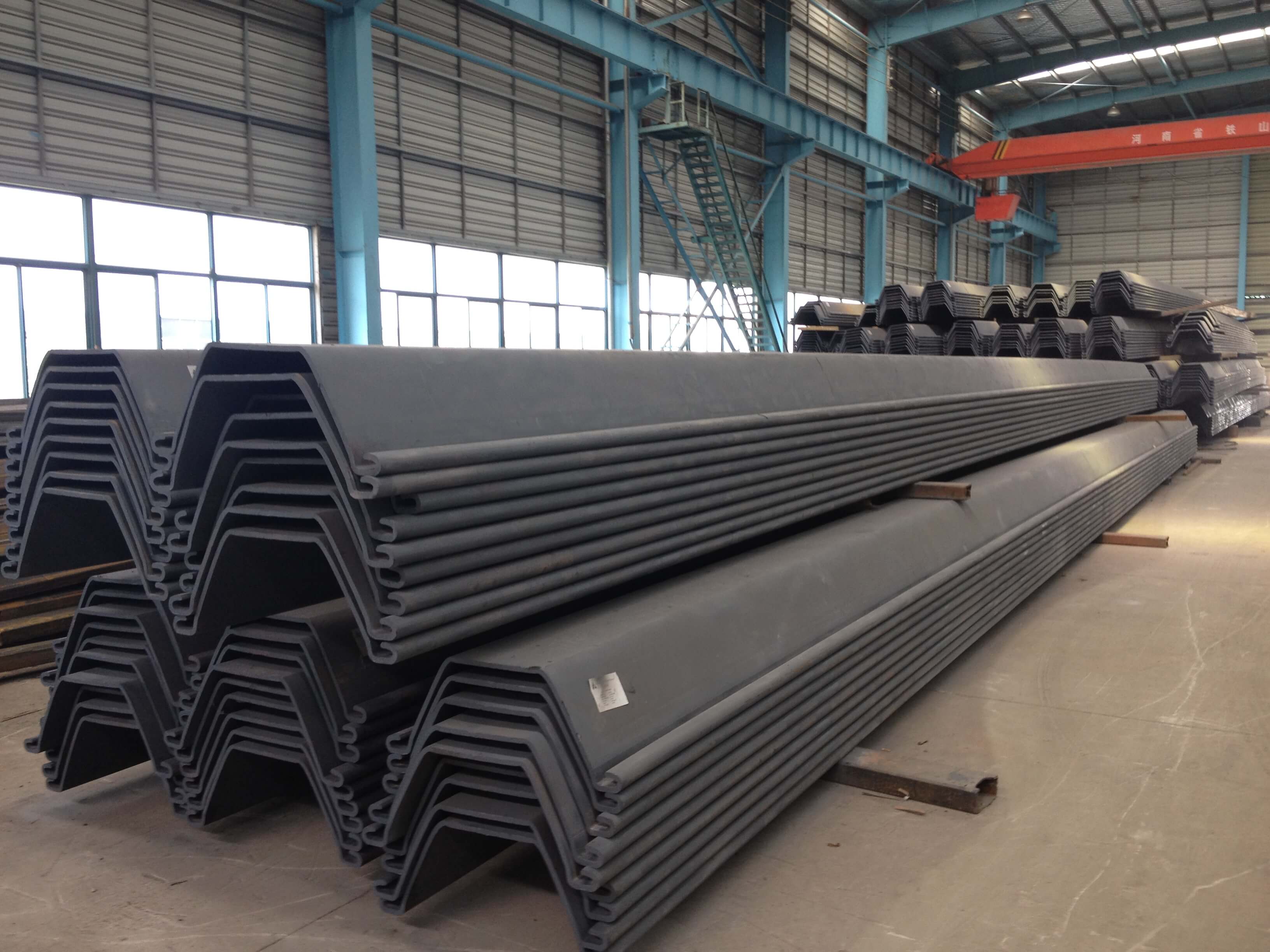

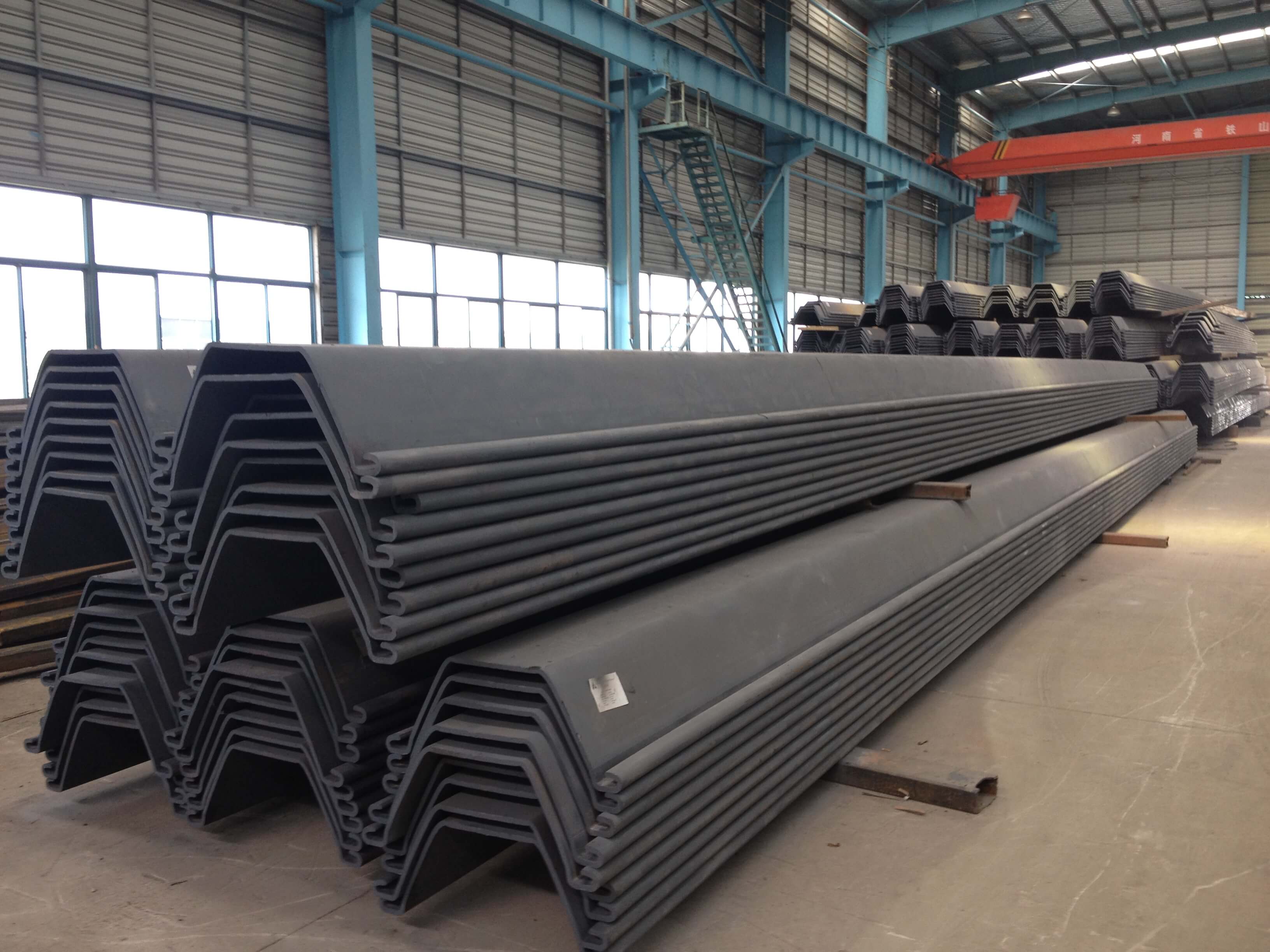

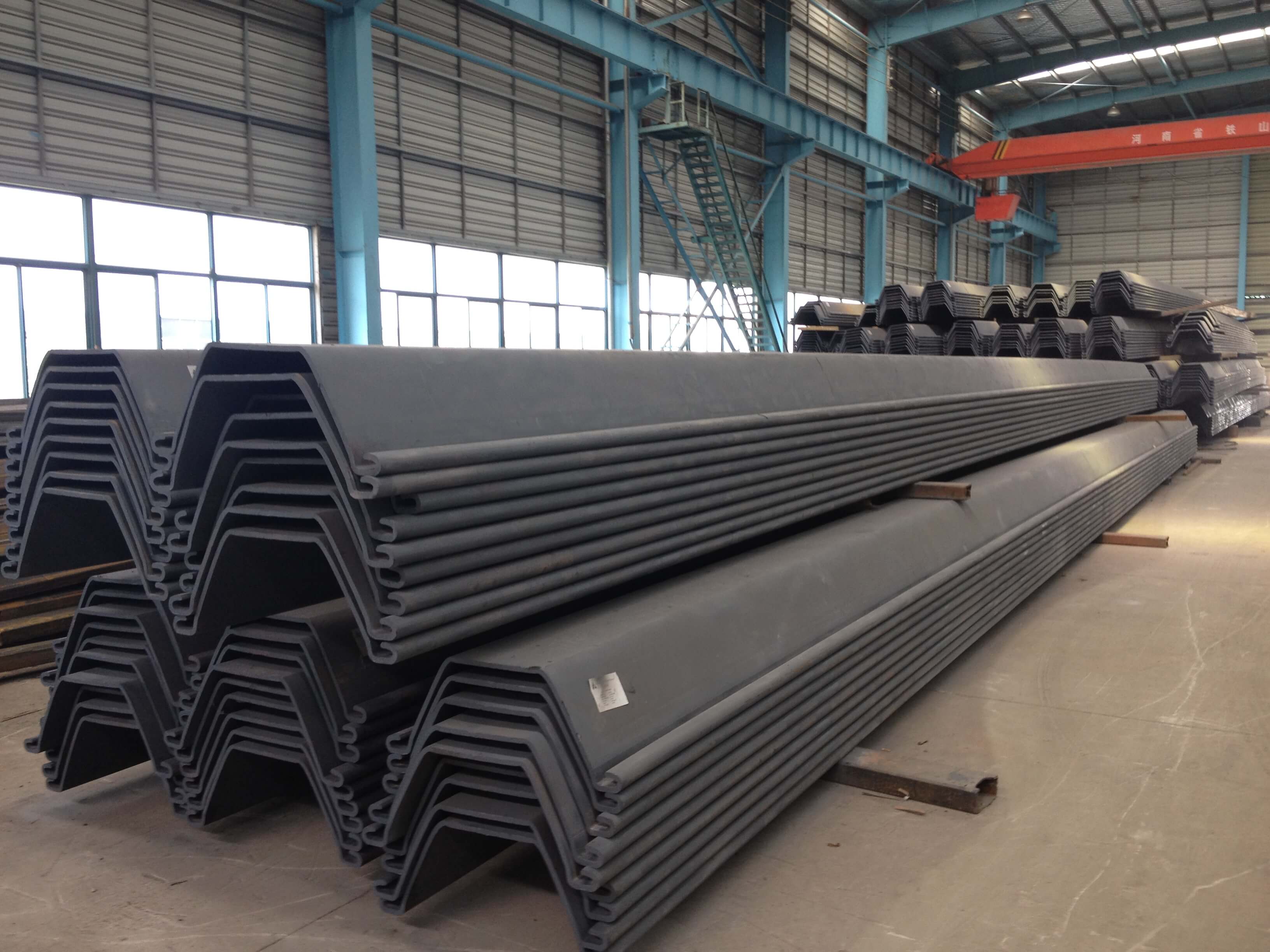

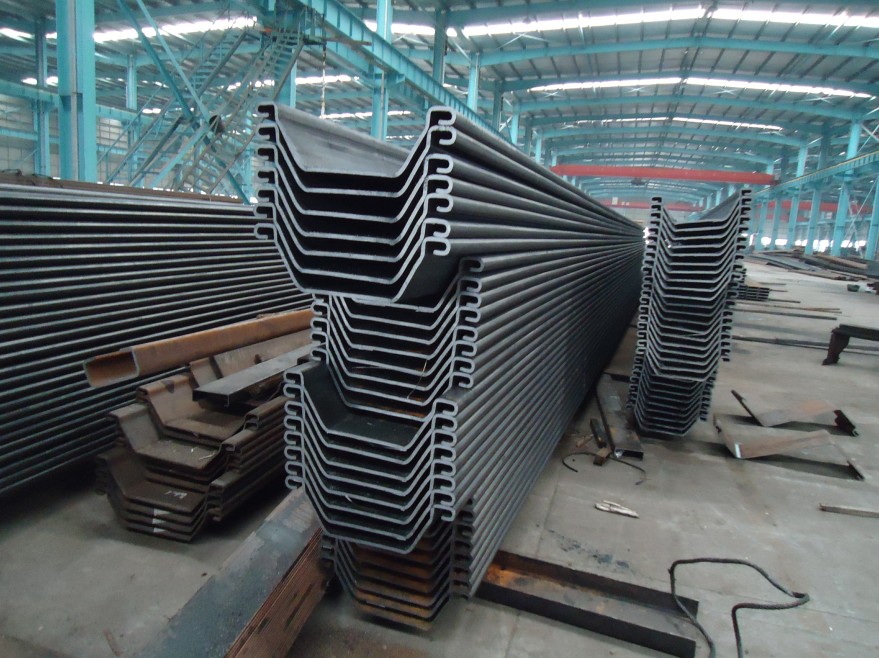

Cold-rolled U type sheet pile is a new technology exsited in late 20th century. Compared to old-fashioned Larssen Sheet Piles, the cold-rolled U Sheet Piling have got the following advantages:

1. Providing equivalent or better section properties (modulus) with lower material cost, which means the unit weight per square meter is lower than larssen sheet piles. This will help save material cost and as result save project cost.

2. Wider than larssen sheet piles. Less quantity or pieces of sheet piles would be needed, which will speed up the installation process. This will help save project time and as a result help save machine and labor cost.

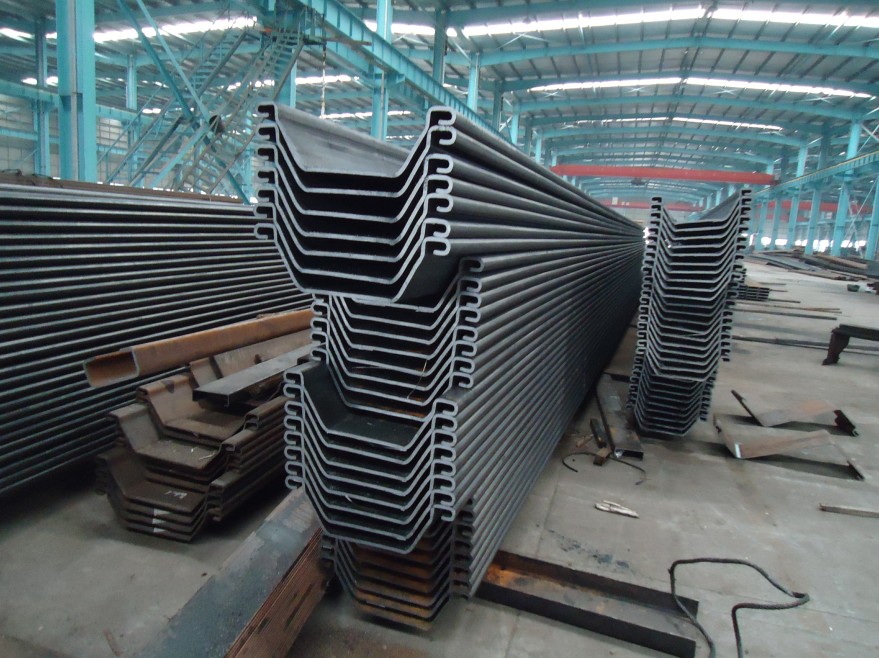

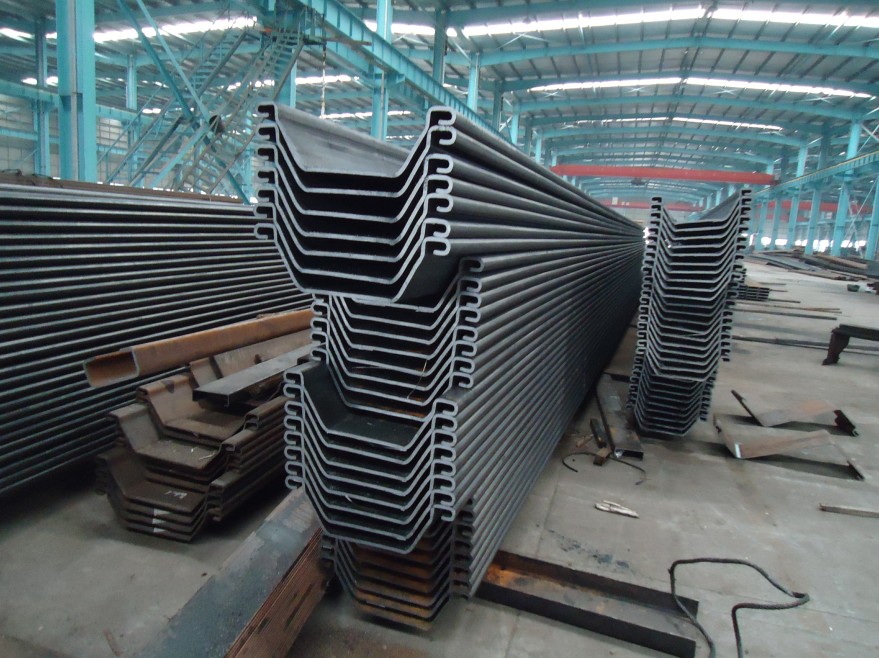

3. Uniform thickness. Compared to Larssen sheet piles, of which the thinnest part at the interlock part is only around 6.5mm, uniform thickness makes it much more stable during installation and it won't be easily damaged during installation.

U sheet pile normally would be delivered in single pile, and somtimes will be delivered in box pile form as per the project design. The height of the U Sheet Piling is always the height of combined pile (double pile).

Product Production Range:

Thickness: 4-16mm

Length: Not limited, as per buyer's request.

Customized designs are also available and welcomed in our company.

Coating and anti-corrosion job is also available for U sheet piles in our mill.

Material: Q235B, Q345B, S235, S240, SY295, S355, S430, S460, A690, ASTM A572 Grade 50, ASTM A572 Grade 60. All Chinese Standard, EN Standard, ASTM Standard and other standard material are available on request.

Manufacturing & Inspection Standard: EN10249-1 / EN10249-2